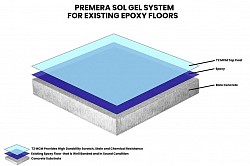

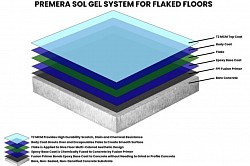

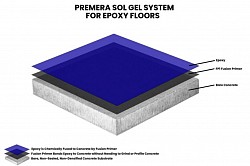

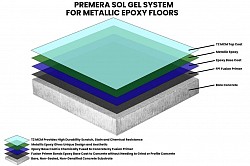

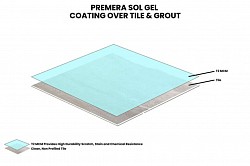

Applicable Substrates, Bare concrete, Polished concrete, Stained concrete, Epoxy floor, Metallic epoxy, Flaked floor, Stone / Tile, Terrazzo.

Top Coat ( opcional )

● DESCRIPTION

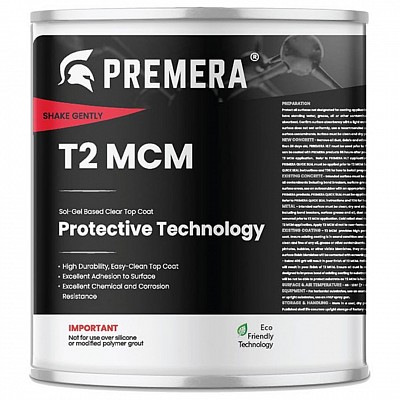

Premera T2 MCM is a solvent-based quartz based clear coating designed to protect metal, concrete and masonry surfaces by creating an integral, long-lasting barrier that provides superior resistance to mold, mildew, moss, rust, moisture, corrosion, chlorides & salt spray, acid rain, UV damage, oxidation, galvanic corrosion, animal & bird waste damage, gum, graffiti and ice adhesion. Durable, wear resistant coating avoids common coating failures like peeling or flaking. T2 MCM can be applied over tinted or un-tinted Premera AT1 QSE for a complete concrete protection system.

● FEATURES

Excellent abrasion and scratch resistance Excellent impact resistance Superior resistance to rust, moisture, corrosion, salt spray, acid rain, oxidation … Resistant to wind drag, dirt build up, ice buildup and animal and bird waste damage UV resistant Virtually invisible Reduced maintenance costs Extended life of the substrate Non-breathable vapor barrier

● TYPICAL USES

Can be applied on Ferrous metals including: Iron, steel, stainless steel, galvanized steel; Non-Ferrous metals including aluminum, copper and bronze (raw, powder coated, painted or primed). Concrete walls, structures, floors, masonry pavers, unglazed tile, bricks and cement block. Moisture, corrosion/rust, oxidation, galvanic corrosion, acid rain, food and beverage acids, fuels and oils, wind drag, dirt build up, ice buildup and animal and bird waste damage. UV stable.

● COLORS

Clear to slight amber to rose (depending on temp and humidity) always dries clear. Gloss or Satin finish. Also available with one of 20 translucent color stains.

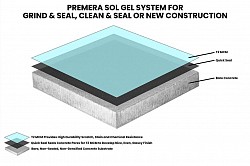

Bare Concrete

Concrete is a great, cost effective material for a floor, but must be protected to maintain its appearance and allow for easy maintenance. Premera T2 MVM do not require grinding concrete in order to obtain excellent adhesion to a concrete floor, which significantly speeds up installation. Premera T2 MCM provide excellent stain and chemical protection, and are also highly abrasion resistant and easy to clean which creates a durable, low maintenance and easy-clean floor finish.

● Very fast application speed

● No surface grinding / profiling required

● Fast return to service and quick / easy job clean up

● Engineered for heavy traffic including forklifts and vehicles

● More durable & cost effective than commonly used thin-mil coatings or tile

● Stain resistant to acids, bases, hydrocarbons / oils, food & drink, cleaning & industrial chemicals

● Easy to clean and maintain

● Thermal shock resistant

● Slip resistant even when wet

● Super anti-slip grip options

● Works on walls / vertical surfaces

● Antimicrobial / antibacterial options

● Suitable for extreme hot and cold environments

● Premera T2 MCM do not require any grinding or profiling of concrete to obtain excellent adhesion, significantly increasing installation speed of coating systems applied on top and eliminating clean up time from dust producing surface prep.

Ultimate Top Coat ( Optional )

Coval UTC IS A THIN FILM, SINGLE COMPONENT COATING DESIGNED TO PROTECT FINISHED SURFACES AND DECORATIVE COATINGS FROM SURFACE WEAR AND HARSH CHEMICALS.

IUltimate Epoxy, Terrazzo, Fiberglass Restoration, Keep Wood Looking Good.

Protectiont creates a covalent bond with the coating substrate and is easily and quickly applied with an acetone pump sprayer or HVLP sprayer.

Coval UTC builds an irreversible covalent bond through the available polar groups in epoxies, urethanes, and paints. This prevents moisture, stains, chloride ion penetration, dirt, ice, acids, animal waste, and graffiti damage to the substrate.

Matting Agent.

The new Coval Matting Agent is designed to transform Coval gloss finish products into satin or matte finishes.

This allows for greater flexibility for the end user when the single gloss-based product is matched to the proportioned amount of matting agent for the desired finish.

Top Coat ( Optional )

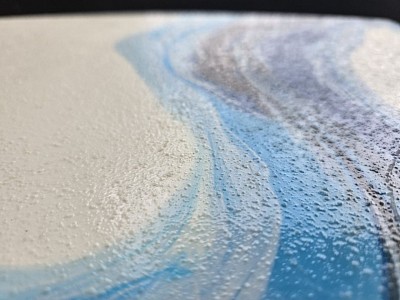

Urethane finishes are essential for increasing chemical and UV resistance. Considered a high-performance product, they offer top overall ratings for abrasion and chemical resistance. They can be clear, matte, or gloss.

Top Coat ( Optional )

Sand can be added to a top coat to create a non-slip surface, (optional) Abrasive materials, such as aluminum oxide, in the non-slip coating provide grip for feet, even in wet conditions. Be sure to apply the non-slip coating to the entire floor for best results. A quick fix for wet and slippery epoxy floors